Analysis of Lithium Battery Protection Board and Battery Protection System

Release time:2025-01-07 19:08:02

Article source:

Haiye Technology (Shenzhen) Co., Ltd

Lithium batteries, with advantages such as high energy density and long cycle life, are widely used in electronic products, new energy vehicles and other fields. During the use of lithium batteries, lithium battery protection boards and battery protection systems play a crucial role. They act like the "safety guards" of lithium batteries, ensuring their safe and stable operation. However, there are obvious differences between the two in terms of definition, composition and function.

Lithium battery protection board

The lithium battery protection board is equipped with core functions such as overcharge protection, overdischarge protection, overcurrent protection and short-circuit protection. Take the lithium battery of a mobile phone as an example. When a mobile phone is charging, if the battery voltage reaches the overcharge protection threshold (generally around 4.2V), the protection board will immediately cut off the charging circuit to prevent the battery from bulging, catching fire or even exploding due to overcharging. When the battery voltage drops to the over-discharge protection threshold (usually around 2.75V) during the use of the mobile phone, the protection board will automatically cut off the discharge circuit to prevent the battery from over-discharging, which could lead to performance decline and shortened lifespan. In addition, when the battery charging and discharging current is too large or a short circuit occurs, the protection board can also respond promptly and quickly cut off the circuit to ensure the safety of the battery and the equipment.

Battery protection system

The Battery Protection System (abbreviated as BPS) is a more complex and comprehensive system with more comprehensive functions. It not only contains the basic functions of the lithium battery protection board, but also integrates more advanced monitoring, management and control functions. A battery protection system is typically composed of multiple components such as sensors, data acquisition modules, control modules, and communication modules.

Sensors are responsible for collecting various parameters of the battery in real time. Besides voltage, current and temperature, they may also include key information such as the battery's SOC (State of Charge) and SOH (Health status). The data acquisition module converts the analog signals collected by the sensors into digital signals, and conducts preliminary processing and filtering to ensure the accuracy and stability of the data. The control module is the core of the battery protection system. It analyzes and judges the collected data based on preset algorithms and strategies, and then issues corresponding control instructions. The communication module enables information interaction between the battery protection system and external devices (such as the vehicle controller, charger, etc.), allowing the system to receive external instructions in a timely manner and feedback the status information of the battery.

Compared with lithium battery protection boards, battery protection systems have more diverse functions. In addition to the basic overcharge, overdischarge, overcurrent and short-circuit protection, it also has a battery balancing management function. By adjusting the voltage between each battery cell, it keeps the power of each cell in the battery pack consistent, effectively improving the overall performance and service life of the battery pack. The thermal management function can automatically adjust the speed of the cooling fan or start the heating device according to the temperature of the battery, ensuring that the battery operates within an appropriate temperature range. The fault diagnosis and early warning function can promptly detect potential faults in the battery system and send early warning information to users through sound and light alarms or communication methods, facilitating users to take timely measures for maintenance and handling. In the field of new energy vehicles, battery protection systems can precisely manage battery packs composed of hundreds or even thousands of individual battery cells, ensuring the safe operation and range of the vehicle.

Although lithium battery protection boards and battery protection systems are different, they are both dedicated to ensuring the safety and performance of lithium batteries. The lithium battery protection board is the basic protection unit, while the battery protection system is a more advanced and comprehensive protection solution. With the continuous expansion of the application fields of lithium batteries and the continuous progress of technology, lithium battery protection boards and battery protection systems will also be constantly upgraded and improved, providing more reliable guarantees for the safe and efficient operation of lithium batteries.

Lithium battery protection board

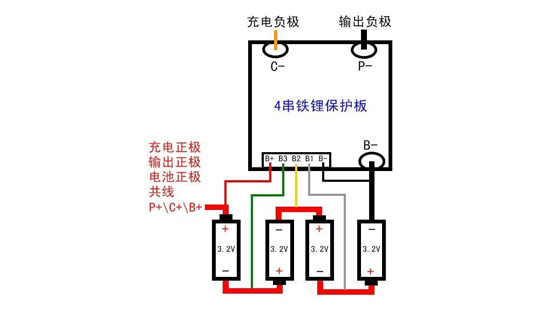

The Lithium Battery Protection Board (BMS for short) is the charge and discharge protection for series lithium battery packs. It is usually composed of electronic components such as control ics, MOSFETs, resistors, and capacitors, and exists in the form of a circuit board. It is an indispensable component in lithium battery packs.

The lithium battery protection board is equipped with core functions such as overcharge protection, overdischarge protection, overcurrent protection and short-circuit protection. Take the lithium battery of a mobile phone as an example. When a mobile phone is charging, if the battery voltage reaches the overcharge protection threshold (generally around 4.2V), the protection board will immediately cut off the charging circuit to prevent the battery from bulging, catching fire or even exploding due to overcharging. When the battery voltage drops to the over-discharge protection threshold (usually around 2.75V) during the use of the mobile phone, the protection board will automatically cut off the discharge circuit to prevent the battery from over-discharging, which could lead to performance decline and shortened lifespan. In addition, when the battery charging and discharging current is too large or a short circuit occurs, the protection board can also respond promptly and quickly cut off the circuit to ensure the safety of the battery and the equipment.

Battery protection system

The Battery Protection System (abbreviated as BPS) is a more complex and comprehensive system with more comprehensive functions. It not only contains the basic functions of the lithium battery protection board, but also integrates more advanced monitoring, management and control functions. A battery protection system is typically composed of multiple components such as sensors, data acquisition modules, control modules, and communication modules.

Sensors are responsible for collecting various parameters of the battery in real time. Besides voltage, current and temperature, they may also include key information such as the battery's SOC (State of Charge) and SOH (Health status). The data acquisition module converts the analog signals collected by the sensors into digital signals, and conducts preliminary processing and filtering to ensure the accuracy and stability of the data. The control module is the core of the battery protection system. It analyzes and judges the collected data based on preset algorithms and strategies, and then issues corresponding control instructions. The communication module enables information interaction between the battery protection system and external devices (such as the vehicle controller, charger, etc.), allowing the system to receive external instructions in a timely manner and feedback the status information of the battery.

Compared with lithium battery protection boards, battery protection systems have more diverse functions. In addition to the basic overcharge, overdischarge, overcurrent and short-circuit protection, it also has a battery balancing management function. By adjusting the voltage between each battery cell, it keeps the power of each cell in the battery pack consistent, effectively improving the overall performance and service life of the battery pack. The thermal management function can automatically adjust the speed of the cooling fan or start the heating device according to the temperature of the battery, ensuring that the battery operates within an appropriate temperature range. The fault diagnosis and early warning function can promptly detect potential faults in the battery system and send early warning information to users through sound and light alarms or communication methods, facilitating users to take timely measures for maintenance and handling. In the field of new energy vehicles, battery protection systems can precisely manage battery packs composed of hundreds or even thousands of individual battery cells, ensuring the safe operation and range of the vehicle.

Although lithium battery protection boards and battery protection systems are different, they are both dedicated to ensuring the safety and performance of lithium batteries. The lithium battery protection board is the basic protection unit, while the battery protection system is a more advanced and comprehensive protection solution. With the continuous expansion of the application fields of lithium batteries and the continuous progress of technology, lithium battery protection boards and battery protection systems will also be constantly upgraded and improved, providing more reliable guarantees for the safe and efficient operation of lithium batteries.