Common causes and solutions of lithium Battery protection boards

Release time:2025-01-07 19:08:00

Article source:

Haiye Technology (Shenzhen) Co., Ltd

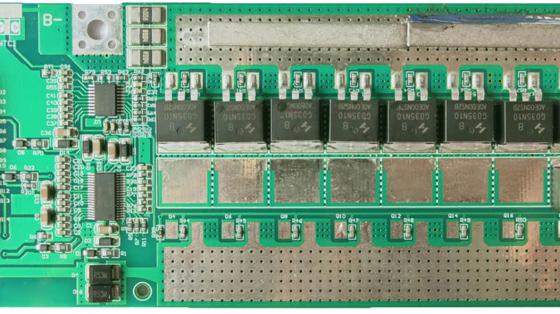

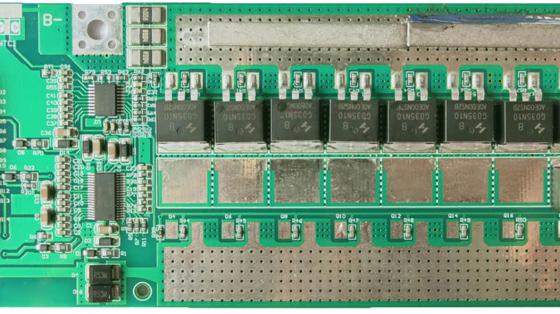

As a key component for the safe operation of lithium batteries, the stability of the performance of the lithium battery protection board is of vital importance. However, in actual use, the protection board may encounter various adverse conditions, which can affect the normal charging and discharging as well as the service life of lithium batteries. Understanding the reasons behind these adverse phenomena and mastering the corresponding solutions can help enhance the safety and reliability of lithium battery usage.

I. Causes and Solutions of Hardware Malfunctions

(1) Damage to electronic components

Cause analysis: The control IC, MOSFET, resistors, capacitors and other electronic components on the lithium battery protection board may be damaged due to factors such as overvoltage, overcurrent and high temperature during long-term use. For example, when the battery pack is subjected to an instantaneous high-voltage impact, the control IC may be punctured. Mosfets are also prone to performance degradation or even burnout during frequent large current disconnections. In addition, the quality defects of electronic components themselves, as well as problems such as poor soldering and false soldering during the production process, may also cause the components to malfunction in the early stage of use.

Solution: In the production process, strictly control the procurement quality of electronic components and select components that meet standards and have high reliability. Optimize the welding process to ensure that the components are firmly welded and reduce the phenomena of false soldering and false soldering. When the protection board malfunctions, professional detection equipment such as multimeters and oscilloscopes are used to inspect each component one by one, identify the damaged components and replace them in a timely manner.

(2) Circuit board wiring issues

Cause analysis: The circuits on the circuit board may experience open circuits, short circuits, and other situations due to mechanical stress, corrosion, aging, and other reasons. For instance, when a lithium battery pack is subjected to external force collision or compression, the circuit board lines may break. If the protection board is exposed to a damp and corrosive gas environment for a long time, the circuit will gradually be corroded, leading to a decline in electrical performance and even causing a short circuit fault.

Solution: During the design and use of lithium battery packs, full consideration should be given to the protection of the protective board to prevent it from being damaged by external forces. For protective boards in harsh environments, measures such as applying three-proof varnish can be taken to enhance the anti-corrosion ability of the circuits. When circuit problems are found, carefully inspect the circuit direction, use tools such as magnifying glasses and probes to locate broken or short-circuit points, re-solder or repair the circuit, and replace the entire circuit board if necessary.

Ii. Causes and Solutions for Software and Parameter Setting Defects

(1) Control program error

Cause analysis: If the program running in the control IC of the protection board has problems such as writing errors, vulnerabilities or incompatibility, it will cause abnormal functions of the protection board. For instance, if the overcharge and overdischarge protection thresholds in the program are set unreasonably, it may cause the protection board to mistakenly trigger protection before the battery reaches a dangerous state, or fail to provide timely protection when the battery is already in a dangerous state. In addition, if the program experiences interruptions or incorrect writes during the upgrade process, it will also cause damage to the program.

Solution: During the software development stage, conduct thorough testing and verification to ensure the program's logic is correct and its functions are stable. For the protection boards that have been put into use, if any program issues are found, the control IC can be updated or repaired through professional programming equipment. Meanwhile, establish a strict program upgrade process to avoid malfunctions during the upgrade process.

(2) Improper parameter Settings

Cause analysis: The various protection parameters of the protection board, such as overcharge voltage, overdischarge voltage, and overcurrent value, need to be precisely set according to the characteristics of the lithium battery. If the parameter Settings are inaccurate, the battery may not be effectively protected. For example, if the overcurrent value is set too high, when the battery shows a large abnormal current, the protection board cannot cut off the circuit in time. If the over-discharge voltage is set too low, it will cause the battery to over-discharge and damage its performance.

Solution: Before installing the protection board, thoroughly understand the specification parameters of the lithium battery and accurately set all the parameters of the protection board strictly in accordance with the technical requirements provided by the lithium battery manufacturer. Use professional debugging equipment to calibrate and test the parameters of the protection board to ensure that the parameter Settings meet the actual usage requirements.

Iii. Causes and Solutions of Adverse External Environment and Usage

(1) Influence of environmental factors

Cause analysis: External environmental factors such as excessively high or low temperatures, humid environments, and strong electromagnetic interference can all have an impact on the performance of lithium battery protection boards. For example, in a high-temperature environment, the performance of electronic components on the protection board will decline, which may lead to protection delay or misoperation. In a strong electromagnetic interference environment, the signal transmission of the protection board may be interfered with, affecting its normal operation.

Solution: Provide a suitable working environment for the lithium battery pack and avoid its use in extreme temperatures, humidity or strong electromagnetic interference environments. In high-temperature environments, heat dissipation devices such as heat sinks and fans can be added to lower the temperature of the protection board. In a humid environment, take good moisture-proof measures, such as using sealed casings and desiccants. For occasions prone to electromagnetic interference, electromagnetic shielding treatment should be carried out on the protection board to enhance its anti-interference capability.

(2) Improper use

Cause analysis: During the use of lithium batteries, if users perform improper operations such as overcharging, overdischarging, or short-circuiting, it can cause damage to the protection board. For instance, charging with an unmatched charger may lead to an excessively high charging voltage, triggering the overcharge protection of the protection board and even damaging the components of the protection board. Directly short-circuiting the positive and negative terminals of a lithium battery will generate a momentary large current, which will burn out the MOSFET and other components on the protection board.

Solution: Enhance the publicity and education of lithium battery usage knowledge among users, informing them of the correct usage methods and precautions. Choose chargers and electrical devices that match the specifications of lithium batteries to avoid overcharging, overdischarging and short circuits. Once the protection board is damaged due to improper use, it should be repaired or replaced in a timely manner in accordance with the above-mentioned solutions for hardware faults or software issues.

The reasons for the poor conditions of lithium battery protection boards are diverse, covering multiple aspects such as hardware, software, environment and usage. By conducting in-depth analysis of the causes of defects and taking targeted solutions, the reliability and stability of lithium battery protection boards can be effectively enhanced, ensuring the safe and efficient operation of lithium batteries.

I. Causes and Solutions of Hardware Malfunctions

(1) Damage to electronic components

Cause analysis: The control IC, MOSFET, resistors, capacitors and other electronic components on the lithium battery protection board may be damaged due to factors such as overvoltage, overcurrent and high temperature during long-term use. For example, when the battery pack is subjected to an instantaneous high-voltage impact, the control IC may be punctured. Mosfets are also prone to performance degradation or even burnout during frequent large current disconnections. In addition, the quality defects of electronic components themselves, as well as problems such as poor soldering and false soldering during the production process, may also cause the components to malfunction in the early stage of use.

Solution: In the production process, strictly control the procurement quality of electronic components and select components that meet standards and have high reliability. Optimize the welding process to ensure that the components are firmly welded and reduce the phenomena of false soldering and false soldering. When the protection board malfunctions, professional detection equipment such as multimeters and oscilloscopes are used to inspect each component one by one, identify the damaged components and replace them in a timely manner.

(2) Circuit board wiring issues

Cause analysis: The circuits on the circuit board may experience open circuits, short circuits, and other situations due to mechanical stress, corrosion, aging, and other reasons. For instance, when a lithium battery pack is subjected to external force collision or compression, the circuit board lines may break. If the protection board is exposed to a damp and corrosive gas environment for a long time, the circuit will gradually be corroded, leading to a decline in electrical performance and even causing a short circuit fault.

Solution: During the design and use of lithium battery packs, full consideration should be given to the protection of the protective board to prevent it from being damaged by external forces. For protective boards in harsh environments, measures such as applying three-proof varnish can be taken to enhance the anti-corrosion ability of the circuits. When circuit problems are found, carefully inspect the circuit direction, use tools such as magnifying glasses and probes to locate broken or short-circuit points, re-solder or repair the circuit, and replace the entire circuit board if necessary.

Ii. Causes and Solutions for Software and Parameter Setting Defects

(1) Control program error

Cause analysis: If the program running in the control IC of the protection board has problems such as writing errors, vulnerabilities or incompatibility, it will cause abnormal functions of the protection board. For instance, if the overcharge and overdischarge protection thresholds in the program are set unreasonably, it may cause the protection board to mistakenly trigger protection before the battery reaches a dangerous state, or fail to provide timely protection when the battery is already in a dangerous state. In addition, if the program experiences interruptions or incorrect writes during the upgrade process, it will also cause damage to the program.

Solution: During the software development stage, conduct thorough testing and verification to ensure the program's logic is correct and its functions are stable. For the protection boards that have been put into use, if any program issues are found, the control IC can be updated or repaired through professional programming equipment. Meanwhile, establish a strict program upgrade process to avoid malfunctions during the upgrade process.

(2) Improper parameter Settings

Cause analysis: The various protection parameters of the protection board, such as overcharge voltage, overdischarge voltage, and overcurrent value, need to be precisely set according to the characteristics of the lithium battery. If the parameter Settings are inaccurate, the battery may not be effectively protected. For example, if the overcurrent value is set too high, when the battery shows a large abnormal current, the protection board cannot cut off the circuit in time. If the over-discharge voltage is set too low, it will cause the battery to over-discharge and damage its performance.

Solution: Before installing the protection board, thoroughly understand the specification parameters of the lithium battery and accurately set all the parameters of the protection board strictly in accordance with the technical requirements provided by the lithium battery manufacturer. Use professional debugging equipment to calibrate and test the parameters of the protection board to ensure that the parameter Settings meet the actual usage requirements.

Iii. Causes and Solutions of Adverse External Environment and Usage

(1) Influence of environmental factors

Cause analysis: External environmental factors such as excessively high or low temperatures, humid environments, and strong electromagnetic interference can all have an impact on the performance of lithium battery protection boards. For example, in a high-temperature environment, the performance of electronic components on the protection board will decline, which may lead to protection delay or misoperation. In a strong electromagnetic interference environment, the signal transmission of the protection board may be interfered with, affecting its normal operation.

Solution: Provide a suitable working environment for the lithium battery pack and avoid its use in extreme temperatures, humidity or strong electromagnetic interference environments. In high-temperature environments, heat dissipation devices such as heat sinks and fans can be added to lower the temperature of the protection board. In a humid environment, take good moisture-proof measures, such as using sealed casings and desiccants. For occasions prone to electromagnetic interference, electromagnetic shielding treatment should be carried out on the protection board to enhance its anti-interference capability.

(2) Improper use

Cause analysis: During the use of lithium batteries, if users perform improper operations such as overcharging, overdischarging, or short-circuiting, it can cause damage to the protection board. For instance, charging with an unmatched charger may lead to an excessively high charging voltage, triggering the overcharge protection of the protection board and even damaging the components of the protection board. Directly short-circuiting the positive and negative terminals of a lithium battery will generate a momentary large current, which will burn out the MOSFET and other components on the protection board.

Solution: Enhance the publicity and education of lithium battery usage knowledge among users, informing them of the correct usage methods and precautions. Choose chargers and electrical devices that match the specifications of lithium batteries to avoid overcharging, overdischarging and short circuits. Once the protection board is damaged due to improper use, it should be repaired or replaced in a timely manner in accordance with the above-mentioned solutions for hardware faults or software issues.

The reasons for the poor conditions of lithium battery protection boards are diverse, covering multiple aspects such as hardware, software, environment and usage. By conducting in-depth analysis of the causes of defects and taking targeted solutions, the reliability and stability of lithium battery protection boards can be effectively enhanced, ensuring the safe and efficient operation of lithium batteries.